- Home

- Metal Balls

- Garden Art Metal Ball

- Metal Hemispheres

- Shop

- Hollow Steel Balls

- Large Steel Balls

- Stainless Steel Gazing Balls

- Garden Steel Pattern Balls

- Hollow Brass Balls

- Brass Hemispheres

- Fire Pit Balls

- Stainless Steel Spheres Water Features

- Stainless Steel Globes

- Stainless Steel Water Drop Sculptures

- Stainless Steel Hemispheres

- Carbon Steel Hemispheres

- Hollow Aluminum Balls

- Aluminum Hemispheres

- Company

- Projects

- Contact

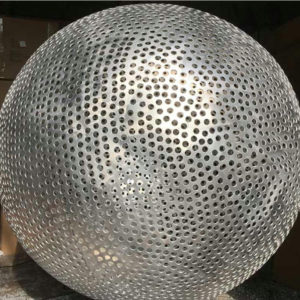

Hollow Aluminum Balls Production Methods

Stamping press

is shaping A6061 aluminum sheet by deforming it with a mould. Then welding two aluminum hemisphere together. finally grinding off the welds and burrs we can stamping press from size ∅19mm to ∅700MM .Thickness available from 1mm to 3MM. This kind of hollow aluminum balls feature a light weight with spray painting for lampshade designs and hanging art elements.

Thickness:1mm to 3MM(20GA to 12GA)

Size Range:∅6mm to ∅700MM(∅ .236inch to ∅27 ½inch)

visible welding seams on the surface

Standard mould limit.

Assembling

is welding A6061 aluminum sheet with man-hand. Our technicals will calculate the specific data for the welding sheet. then bending the leaf shape. and then our qualify workers will weld a entire hollow aluminum balls. finally grinding off welds and burrs. There’s no standard mould limited. Making any size on your demand.

Thickness:1mm to 6MM (20GA to 3GA)

Size range from ∅200mm to ∅3500MM (∅8inch to ∅11½ft)

Visible welding seams and burrs free

None-Standard mould limit